Gate valve

Gate valve is a common type of valve widely used in various pipeline systems, mainly used to cut off or connect fluids. The name of the gate valve comes from its internal structure - a gate perpendicular to the flow direction of the fluid, which can be raised and lowered to control the flow of the fluid.

the gate valve is an important fluid control device, which is favored by the industry for its simple operation, good shutoff ability and wide range of applications.

Contact US

Here are some key features and uses of gate valves:

1.Gate valves working principle:

Gate valves working principle

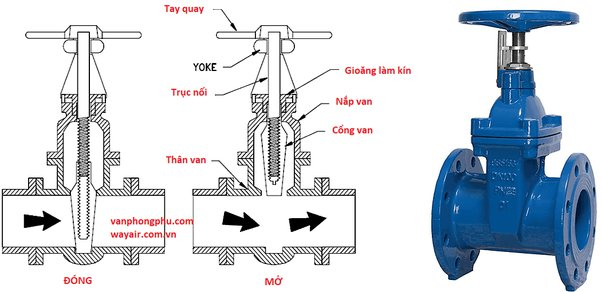

The gate valve is opened or closed by lifting or lowering the gate. When the gate is fully lifted, the fluid channel is fully open; when the gate drops to the valve seat, the fluid channel is closed. The gate can be flat or wedge-shaped, the latter is more common under high pressure difference because it provides better sealing performance.

2. Gate valves structure and material:

The structure of the gate valve usually includes parts such as the valve body, valve cover, gate, valve stem and sealing surface. The valve body and valve cover are usually made of cast iron, carbon steel, stainless steel or other alloy materials to adapt to different working conditions and media. The gate and sealing surface may be made of different materials, such as rubber, plastic or metal, to improve the sealing performance.

3. Gate valves classification:

Gate valves can be divided into manual gate valves and automatic gate valves

according to the operation mode. The former is operated by handwheel or gear, and the latter is operated by electric, pneumatic or hydraulic actuators.

According to the structure, gate valves can be divided into rising stem gate valves and non-rising stem gate valves.

Non-rising stem gate valve

The valve stem of the rising stem gate valve rises and falls with the gate plate, while the valve stem of the non-rising stem gate valve is not exposed, and only the threaded part rotates.

Rising stem gate valve

TThe valve stem of the rising stem gate valve rises and falls with the gate plate, while the valve stem of the non-rising stem gate valve is not exposed, and only the threaded part rotates.

The valve stem of the rising stem gate valve rises and falls with the gate plate, while the valve stem of the non-rising stem gate valve is not exposed, and only the threaded part rotates.

4.Gate valve advantages:

- the advantages of small fluid resistance,

- small force required for opening and closing

- unrestricted medium flow direction

- no disturbance

- no pressure reduction

They are suitable for occasions that require full opening or full closing, but not for occasions where the flow rate is frequently adjusted.

5.Gate valves Application:

Gate valves are widely used in fluid pipelines such as tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electricity, shipbuilding, metallurgy, and energy systems as devices for cutting off or connecting fluids.

Gate valves Application

6.Gate valves Maintenance:

The maintenance of gate valves is relatively simple, mainly including regular inspection of sealing performance, lubrication of valve stems and threaded parts, cleaning of the inside of the valve body, etc. Proper maintenance can extend the service life of gate valves and maintain their good performance.