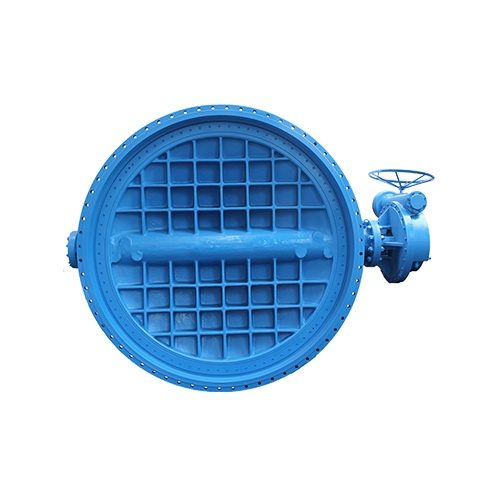

Definition and use of metal hard seal butterfly valve

Metal hard seal butterfly valve is a kind of industrial valve, which adopts metal hard seal structure, which is suitable for high temperature, high pressure, corrosion resistance, wear resistance and other harsh working conditions. The sealing form of this valve usually includes metal-to-metal seal, interchangeable metal seal to metal seal, stainless steel plate and graphite composite plate seal to metal seal, etc. Metal hard seal butterfly valves have various driving forms, including electric, manual, worm gear drive, pneumatic, etc. They are commonly used in petroleum, chemical, metallurgy, hydropower and other industries for medium cutting and regulation in pipeline systems.

The working principle of the metal hard seal butterfly valve

The working principle of a metal hard seal butterfly valve is based on the rotational motion of the butterfly plate in the pipeline. The butterfly plate is mounted in the diameter direction of the pipe and rotates around the axis. The rotation angle is usually between 0° and 90°, and when the rotation reaches 90°, the valve reaches full open. The sealing performance of the metal hard seal butterfly valve is excellent, especially under high temperature and high pressure conditions, and it can still maintain a good sealing effect.

Advantages and disadvantages of metal hard seal butterfly valves

Merit:

- Good sealing, corrosion resistance, long service life.

- It is suitable for high temperature, high pressure, corrosion resistance, wear resistance and other harsh working conditions.

- Compact structure, small size, light weight and easy to operate.

- Simple maintenance, easy to replace the sealing ring.

Shortcoming:

- The cost is relatively high, especially in large valves.

- For some extreme working conditions, special designs or materials may be required.

Metal hard seal butterfly valves are widely used in the following scenarios:

- Oil and gas industry: used to transport oil, natural gas and other flammable and explosive media.

- Chemical industry: used to transport corrosive chemicals, such as acids, alkalis, solvents, etc.

- Metallurgical industry: used for material transportation and cooling water system in the smelting process.

- Hydropower industry: sluice control and cooling system for hydropower stations.

When selecting a metal hard seal butterfly valve, factors such as the nature of the medium, working pressure, and temperature should be considered to ensure that the most suitable valve type is selected.