Butterfly valve

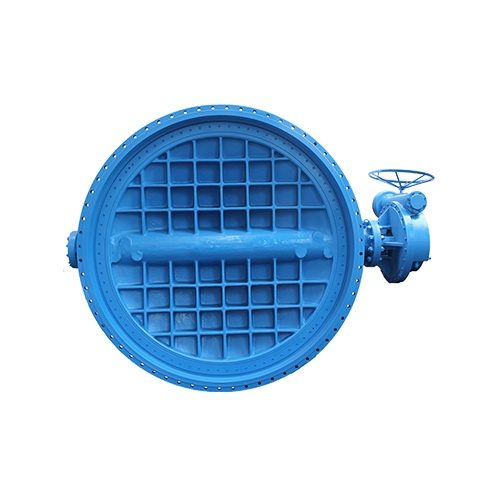

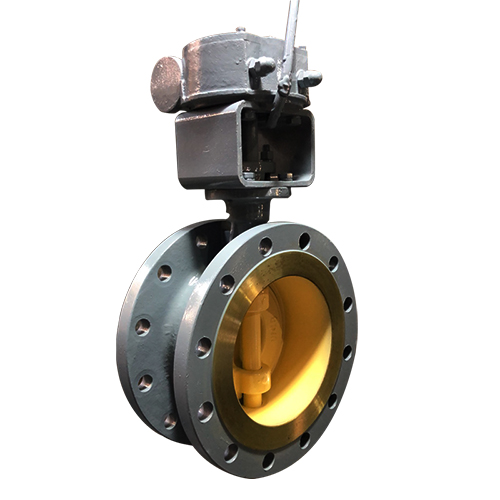

The butterfly valve, also known as the butterfly valve, is a valve widely used in industrial pipeline systems. It consists of a valve body, a valve stem, a butterfly plate and a sealing ring. The valve body is cylindrical, with a short axial length and a built-in butterfly plate. The main function of the butterfly valve is to control the flow of fluid in the pipeline, and can be used to cut off, connect or adjust the flow of the medium.

The working principle of the butterfly valve is relatively simple. When the operating device (such as a manual device, an electric device or a pneumatic device) drives the valve stem to rotate, the valve stem drives the butterfly plate to rotate in the valve body. The rotation angle of the butterfly plate determines the opening degree of the valve, thereby controlling the on-off and flow of the fluid. In the closed state, the sealing surface between the butterfly plate and the valve seat is affected by the fluid pressure to form a reliable seal.

Contact US

Definition and Use of Butterfly Valve

The butterfly valve, also known as the butterfly valve, is a valve widely used in industrial pipeline systems. It consists of a valve body, a valve stem, a butterfly plate and a sealing ring. The valve body is cylindrical, with a short axial length and a built-in butterfly plate. The main function of the butterfly valve is to control the flow of fluid in the pipeline, and can be used to cut off, connect or adjust the flow of the medium.

Working Principle of Butterfly Valve

The working principle of the butterfly valve is relatively simple. When the operating device (such as a manual device, an electric device or a pneumatic device) drives the valve stem to rotate, the valve stem drives the butterfly plate to rotate in the valve body. The rotation angle of the butterfly plate determines the opening degree of the valve, thereby controlling the on-off and flow of the fluid. In the closed state, the sealing surface between the butterfly plate and the valve seat is affected by the fluid pressure to form a reliable seal.

Characteristics of Butterfly Valve

The butterfly valve has the characteristics of simple structure, small size, light weight, low material consumption, small installation size, fast switching, 90° reciprocating rotation, and small driving torque. They are suitable for cutting off, connecting and adjusting the medium in the pipeline, and have good fluid control characteristics and closing and sealing performance. In addition, the streamlined design of the butterfly valve reduces fluid resistance loss and is an energy-saving product.

Application areas of butterfly valves

Butterfly valves are widely used in pipeline systems in coal chemical, petrochemical, rubber, papermaking, pharmaceutical and other industries, mainly used as media diversion and confluence or flow direction switching devices. They are also suitable for flow regulation, especially in the field of large-diameter regulation, because they have less flow resistance when fully opened.

Selection and maintenance of butterfly valves

When selecting a butterfly valve, factors such as its material, size, pressure level, and connection method should be considered to ensure that the selected valve meets the requirements of the specific application scenario. Regular inspection and maintenance of butterfly valves to ensure their normal working condition is essential to ensure the safe operation of the pipeline system.

How to correctly choose the right butterfly valve

When choosing a suitable butterfly valve, you need to consider the following key factors:

- Fluid properties: Understand the properties of the fluid to be processed, such as flow rate, temperature, pressure, viscosity, corrosiveness, etc., and select the appropriate butterfly valve material, sealing material and pressure resistance according to these characteristics.

- Working conditions: Consider the working environment of the butterfly valve, including temperature range, pressure range, medium state (gas or liquid), working frequency, etc., to select the appropriate butterfly valve material, sealing method and structure type.

- Flow requirements: Select the appropriate butterfly valve size according to the flow rate to be adjusted or cut off. The appropriate butterfly valve size is usually calculated by the flow coefficient or formula.

- Corrosion resistance: If the fluid is corrosive, it is necessary to select a butterfly valve made of corrosion-resistant materials. Common corrosion-resistant materials include stainless steel, alloy steel, high-temperature alloy, etc.

- Energy-saving effect: Consider the flow resistance characteristics of the butterfly valve, and select a low-resistance, high-efficiency butterfly valve to reduce energy consumption.

- Maintainability: Consider the structural characteristics of the butterfly valve, and select a butterfly valve that is easy to maintain and replace parts.

- Butterfly valve brand and quality: Choose a well-known brand and a butterfly valve supplier with a good reputation to ensure product quality and after-sales service.

The above steps will help you choose the butterfly valve that best suits your specific application needs. During the selection process, be sure to consider all relevant factors to ensure that your decision is both safe and cost-effective.