Definition and use of flanged butterfly valves

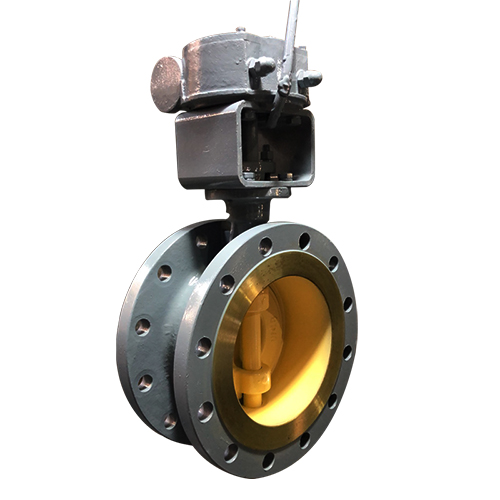

Flanged butterfly valves are a commonly used type of valve that is connected to a pipe by means of a flange connection. This type of valve is mainly used to control the flow of fluids in pipelines, including gases, liquids, etc. Due to its advantages of simple structure, convenient operation and good sealing performance, flanged butterfly valve has been widely used in many industries, such as water treatment, petrochemical, electric power, pharmaceutical, etc.

The working principle of the flanged butterfly valve

The working principle of flanged butterfly valves is relatively simple. When an operating device (such as a manual, motorized, or pneumatic) drives the stem to rotate, the stem drives the butterfly plate to rotate in the valve body. The angle of rotation of the butterfly plate determines how well the valve is opened, thus controlling the on/off and flow of the fluid. In flanged butterfly valves, the realization of sealing performance mainly depends on the tight fit between the butterfly plate and the valve seat. When the valve is closed, the sealing surface between the butterfly plate and the valve seat is subjected to fluid pressure, resulting in a reliable seal.

Features of flanged butterfly valves

- Simple and compact structure: The structural design of the flanged butterfly valve is relatively simple, the number of parts is small, and the installation and maintenance are convenient. At the same time, its compact design allows the valve to take up less space in the piping system, which is conducive to reducing engineering costs.

- Light and flexible operation: Flanged butterfly valves usually adopt manual, electric or pneumatic operation methods, which makes the operation more light and flexible. The operator can open or close the valve at any time as needed, allowing for precise control of fluid flow.

- Good sealing performance: The flange butterfly valve adopts a metal sealing structure and cooperates with elastic seals, so that the valve has good sealing performance in the closed state and can effectively prevent fluid leakage.

- High pressure resistance and corrosion resistance: The flanged butterfly valve is made of high-quality materials and can withstand high pressure and corrosive media. At the same time, its surface has been specially treated, with good corrosion resistance, and can adapt to a variety of media and environmental conditions.

- Superior flow regulation performance: Since the rotation angle of the butterfly plate can be precisely controlled, the flange butterfly valve has superior performance in regulating the flow rate. The operator can adjust the rotation angle of the butterfly plate to achieve precise adjustment of the flow rate to meet different process requirements.

Flanged butterfly valves are used in a wide range of industries such as:

- Water treatment: It is used to control the on-off and regulation of water flow to ensure the normal operation of the water supply system.

- Petrochemical industry: used for flow control and interception operation in the pipeline system to ensure production safety and environmental protection.

- Iron and steel industry: used for the control of high temperature and high pressure medium, suitable for the process piping system of the steel industry.

- Power industry: used for the control of medium pipelines such as boiler system and circulating water system.

- Mining industry: used for flow control of solid particle media.

- Food industry: suitable for the transportation and regulation of liquid food in the food production process.

- Chemical industry: In the process of chemical production, it is necessary to control and regulate the flow of various media.

- Paper industry: It is often used in papermaking machinery to control the flow and pressure of pulp, and is used to produce various types of paper.

- Fire fighting system: control the flow of water, etc.

These areas of application fully demonstrate the importance and versatility of flanged butterfly valves in modern industry.